EOS P 500 system is “effective, energy-efficient, and perfectly aligned with our growth strategy”

“For us, this is a strategic investment,” Prototal CEO Jan Löfving explains.

“The modular platform design will bring immediate operational and throughput benefits to Prototal customers and align perfectly with our future goals in Europe for industrialized 3D printing.”

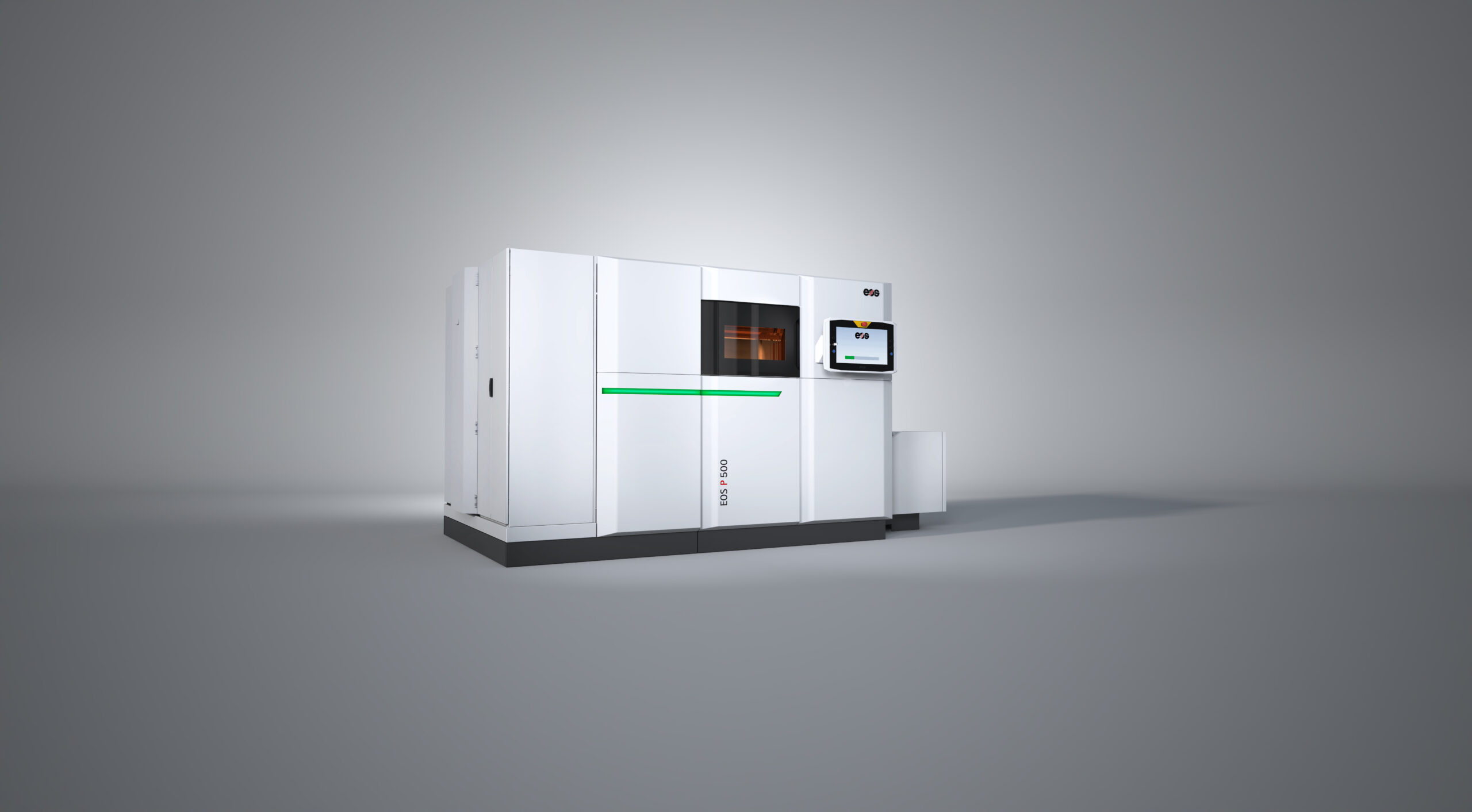

Prototal Industries, Scandinavia’s largest and most specialized additive manufacturing company, recently installed the state-of-the-art EOS P 500 system for plastic laser sintering at Prototal GTP in Ystad as the first of its kind in Northern Europe.

Prototal is renowned for its additive manufacturing services across various industries, including certified parts for aerospace, industrial, medical, and automotive customers, where part quality, repeatability, and productivity are critical. The automated manufacturing platform from EOS supports Prototal’s strategy to meet the requests and demands for industrial 3D printing of plastic parts on an industrial scale.

The P 500 system in Ystad will complement Prototal’s existing machine park, having already two systems installed at 1zu1 in Austria.

Markus Glasser, Senior Vice President EMEA at EOS, adds: “We are very excited that Prototal has selected the EOS P 500 as a key component in its growth plans. This investment is a perfect match, providing a state-of-the-art AM system to a state-of-the-art end-to-end production partner setting up a digital production with these platforms.” He continues: “We have enjoyed a long-standing relationship with Prototal and look forward to further increasing our strategic partnership, which will set new standards in industrial 3D printing adoption.”

“We will, as a pilot, process high-performance polyamide made from 100% renewable castor beans.” Says Jan Löfving, CEO of Prototal.

The build speed of the EOS P 500 is twice as high compared to the next fastest laser-sintering system on the market (being the EOS P 396). The P 500 excels in its high speed without compromising process stability or part quality thanks to sophisticated temperature management, which improves manufactured parts’ dimensional accuracy, material properties, and homogeneity.

Prototal considered different manufacturers when selecting the additive manufacturing system to join its existing stable of EOS and other machines. Prototal chose the EOS P 500 because of its outstanding ability to deliver industrial-scale 3D printing with quality, speed, and flexibility. It also enables 24/7 productivity and supports digital production control through a selection of software solutions. Connectivity features allow the machine to be monitored closely for quality assurance maintaining build parameters.

You may also like

Categories

- Android (3)

- Antivirus (1)

- Artificial Intelligence (AI) (20)

- Automobili (6)

- Bitcoins (6)

- Blockchain (8)

- CAREER (18)

- Cloud Computing (15)

- Cybersecurity (28)

- DEVELOPMENT (20)

- Digital Transformation (62)

- EDUCATION (20)

- FINANCE (99)

- HEALTHCARE (98)

- Home Security Systems (2)

- IGAMING (12)

- Internet of Things (IoT) (28)

- Laptops (8)

- NEWS (351)

- Printers (2)

- PRODUCTS (90)

- RETAIL (31)

- Routers (8)

- SECURITY (60)

- Servers (13)

- SERVICE (12)

- Smartwatches (2)

- Storage (2)

- Streaming Devices (13)

- SUSTAINABILITY (56)